From the Check Engine Light to the Check Elbow Light

The auto industry spends over $40B globally per year on warranty. One of the contributors to this is the Check Engine Light. This light is the result of the California Air Resources Board's On Board Diagnostics regulations, commonly referred to as OBD2. The premise of this regulation is that any component that compromises the vehicle’s tailpipe emissions resulting in 1.5 times the legal limit, shall turn on the check engine light. There are hundreds of reasons that this light can come on from oxygen sensors, temperature sensors, catalysts, etc. I have spent the last twenty years of my career obsessing over the Check Engine Light.

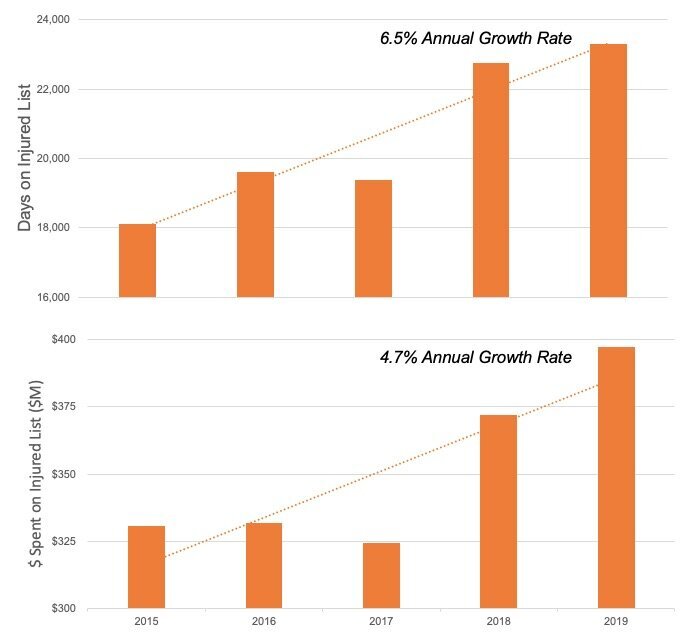

Avoiding OBD2 false failures and launching vehicles with good quality is critical to avoiding warranty. So how does this relate to baseball? In the last five years, MLB teams have paid over $1.7B to pitchers while they were on the injured list. In 2019, over 22,000 days were spent on the injured list by pitchers. In terms of seasons, this is equivalent to the complete pitching staff of 10 MLB teams, a third of the league, missing the entire season. Like the auto industry, MLB is suffering from excessive warranty and product quality problems. What if there was a diagnostic system that could identify if a pitcher was at risk of injury?

The team at DVS Baseball has developed a methodology called the Delivery Value System which evaluates the mechanical efficiency of the pitching delivery by analyzing six different components in the delivery resulting in a DVS Score. This score is a key input into the DVS Injury Risk (IR) model which predicts the likelihood of injury as a function of future innings pitched. When comparing two pitchers, version 1.0 of the IR model could reliably pick which pitcher would get injured first 70.3% of the time. This provides significant value to clubs in player personnel and development decisions.

I am now turning my obsession over to what I call the Check Elbow Light. We are working diligently on the IR model to improve its diagnostic capability for injury prediction. This begins with increasing the components of the DVS score from six to over thirty. We are also adding Statcast data to include performance, in-depth usage information and more to the model. In addition to version 2 of the IR model, I’ll be leading all of our product development activities. Highlights of this include our new DVS Bullpen app, an athlete management platform designed specifically for pitchers, cloud and data strategies, the back end of our Mechanics for Velocity & Performance, M.V.P., pitching development online training system, and other analytics R&D projects. I’m excited to be lacing it up with this great team, great things are in store, stay tuned!